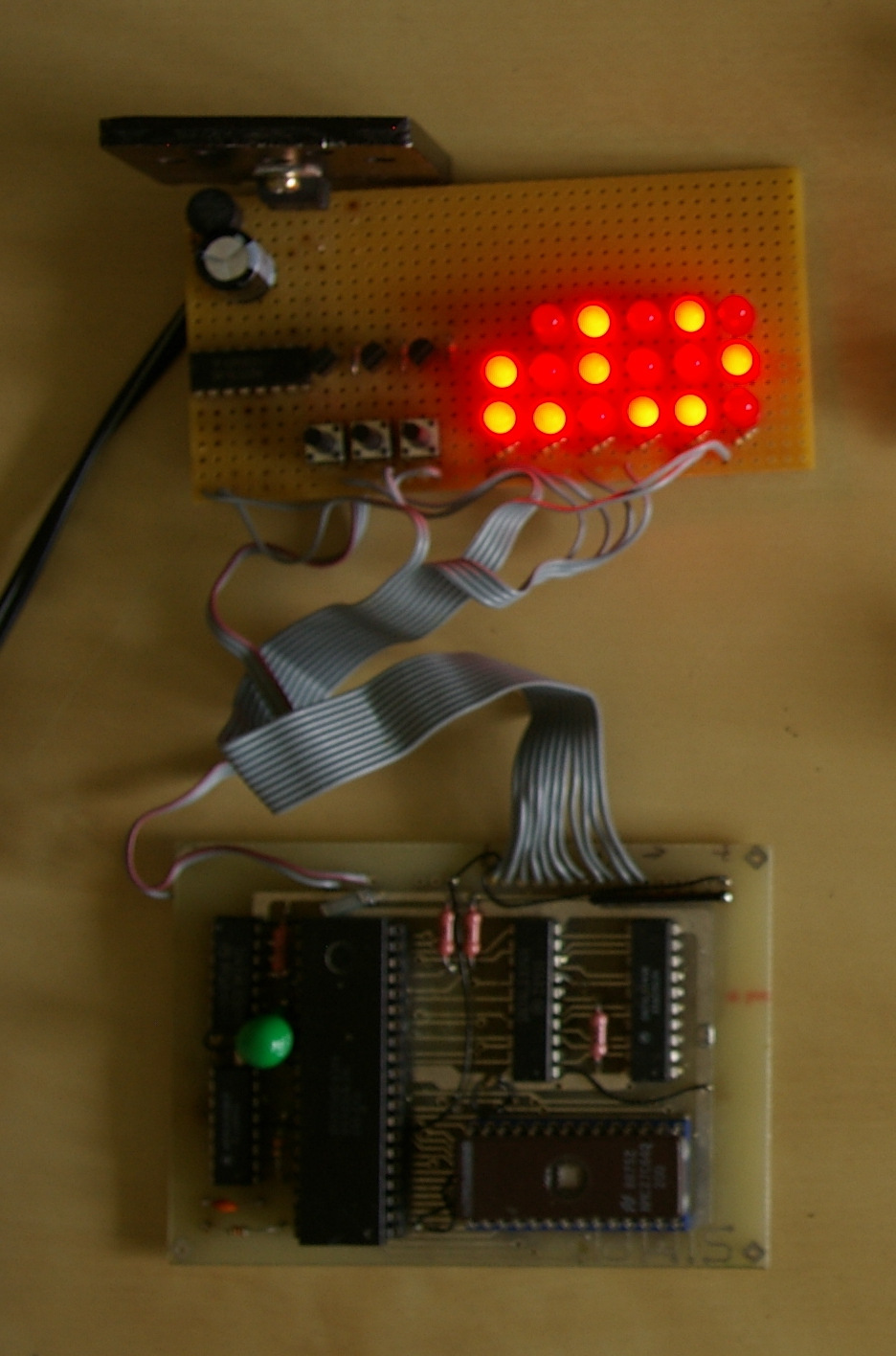

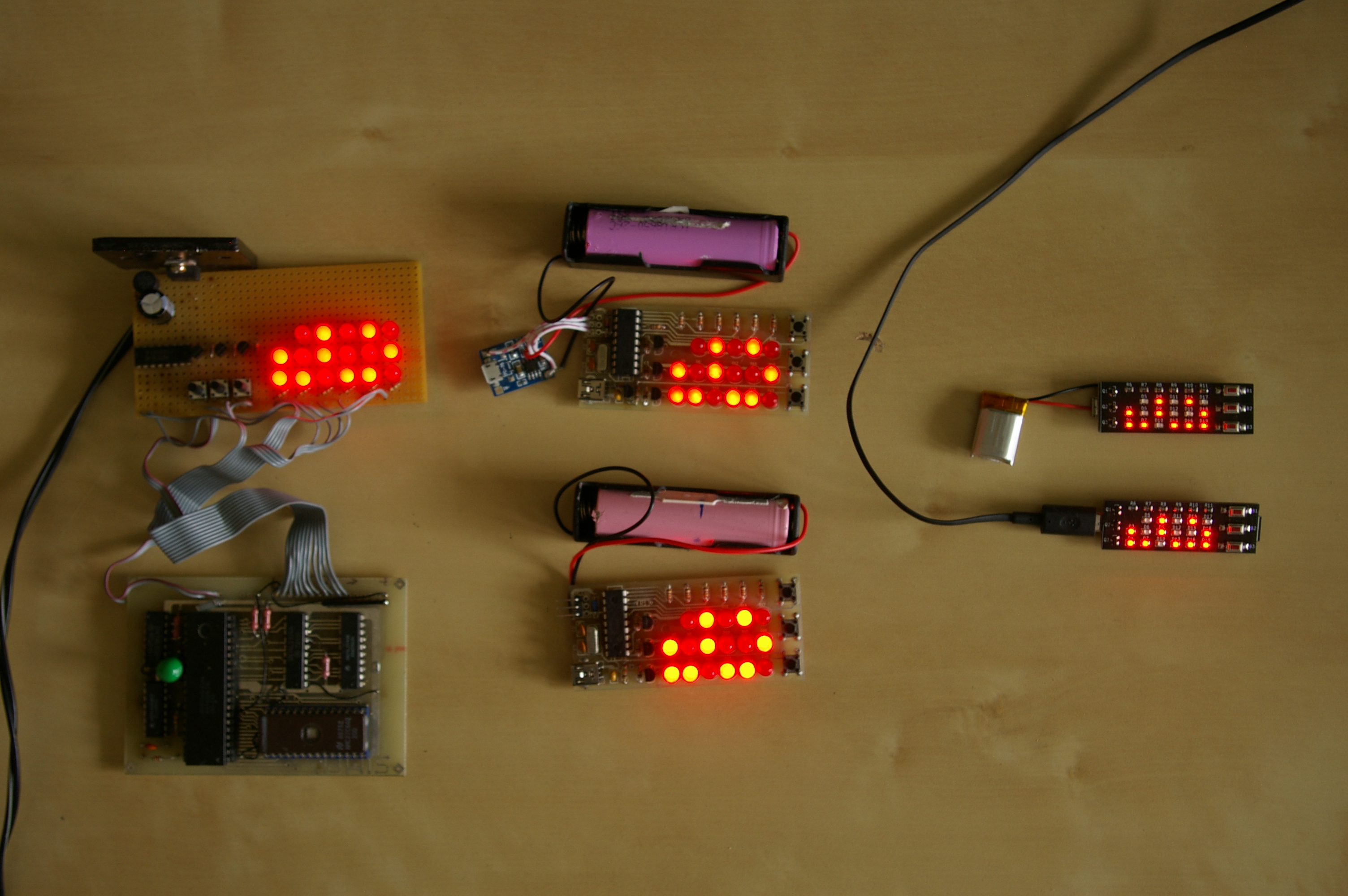

Date: 2011 - 2012. What can I do with my old Z80 board, which I bought in the late 80s? I ordered this panel from the 'Mikroszamitogep Magazin 1987/8'. You can read all the three pages about the board here, here, and here. I modified the board a little bit: i.e. I changed the output latch (74LS273) to another one (74LS374)

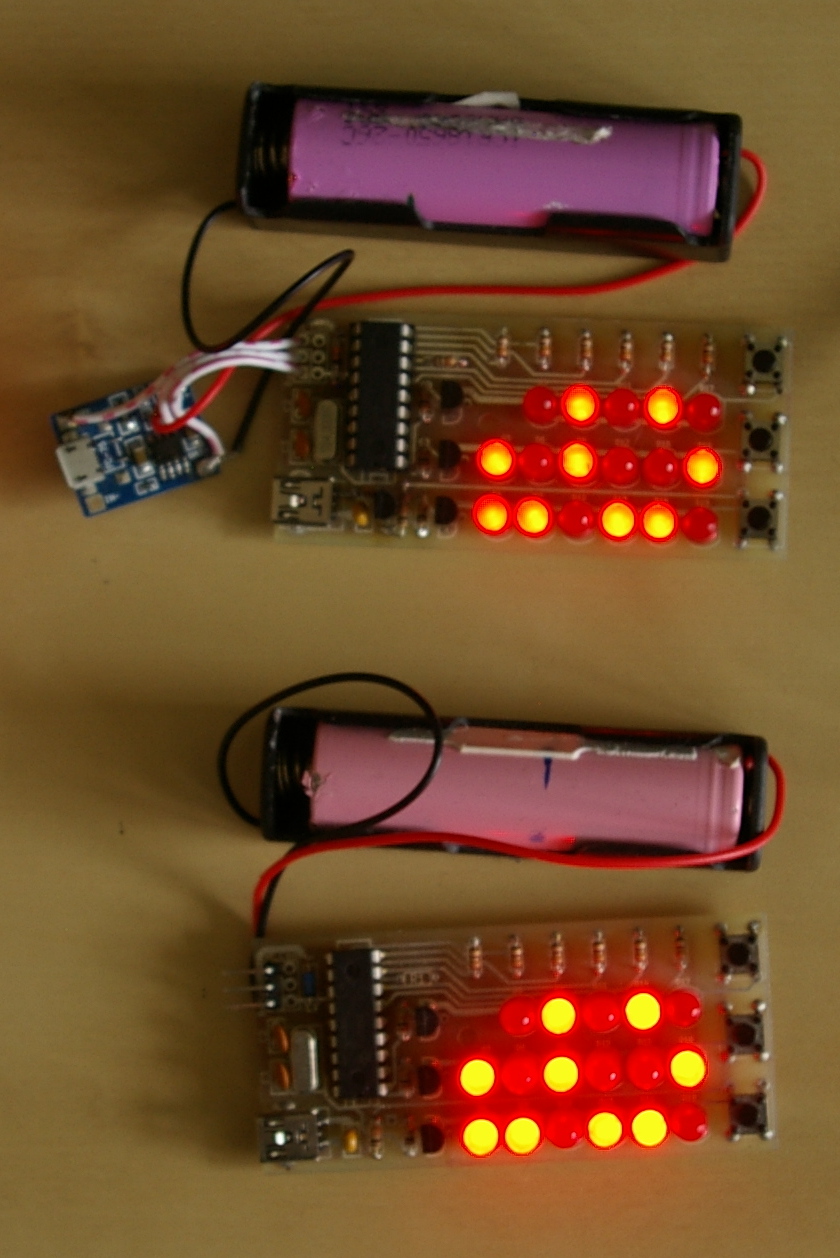

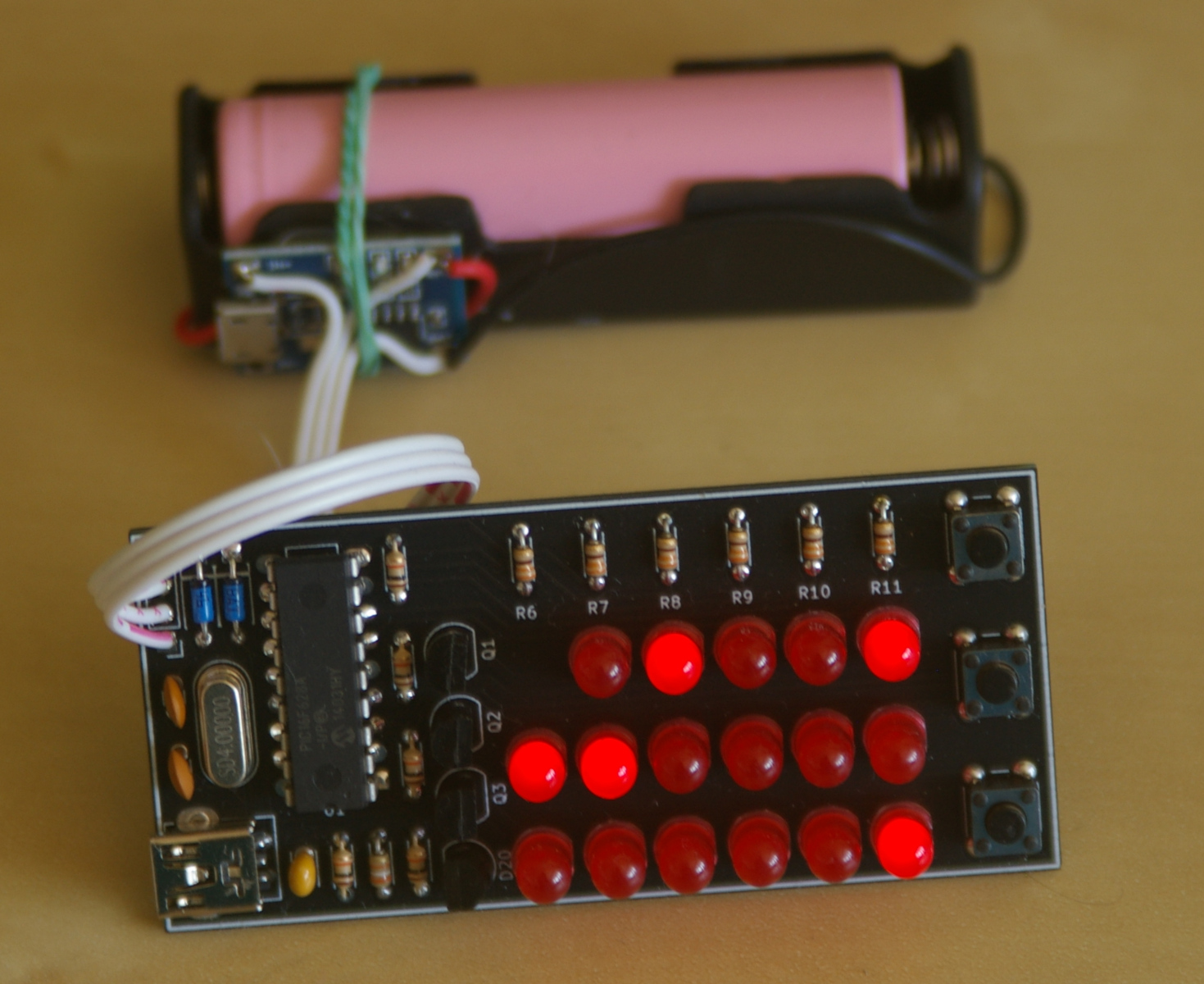

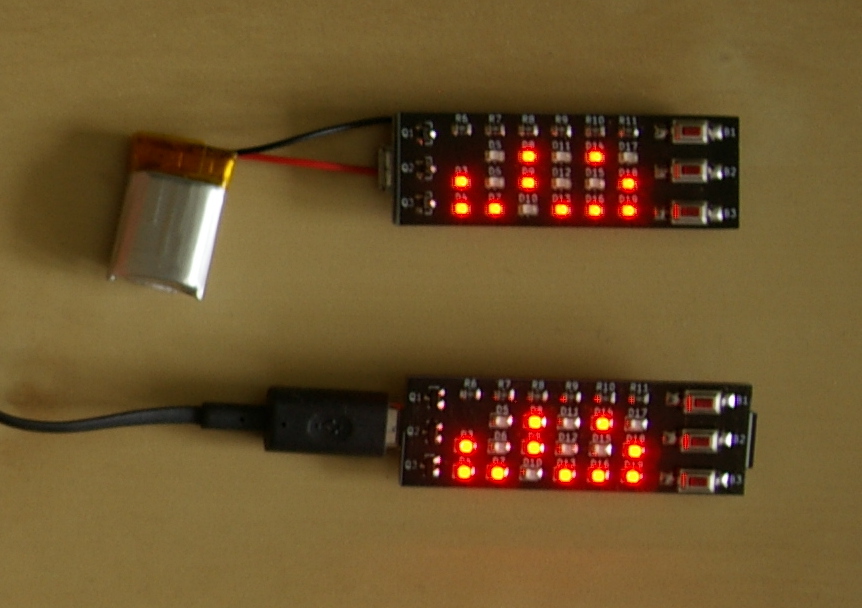

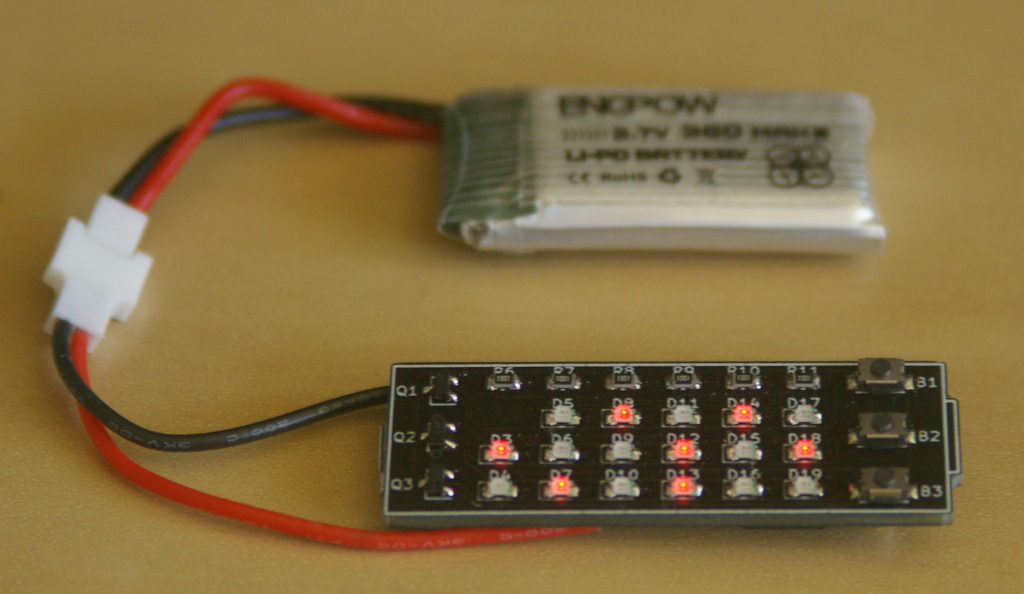

The main problem with this board was that it has only eight outputs. How can I control directly 17 LEDs on 8 bits? If I make a compromise, and the clock will not be able to show 24 hours (only 12), then the 8 bits would be enought for 16 LEDs in a 4x4 matrix. But I wanted a 24 hours display! So I had to extend the 8 bits. The lower 6 bits were the digits, and the higher 2 bits ensured the row control. To extend 2 bits to 3 rows, I used an external demultiplexer circuit (74LS138).

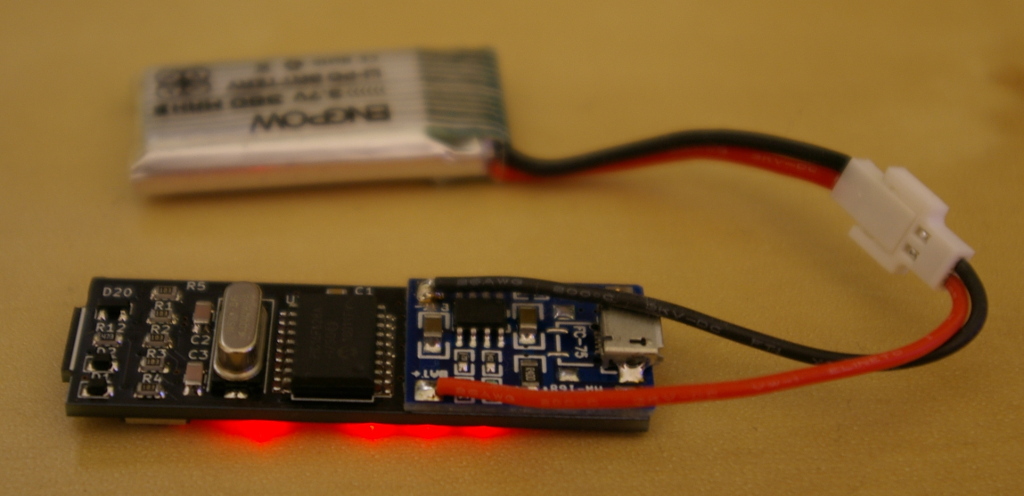

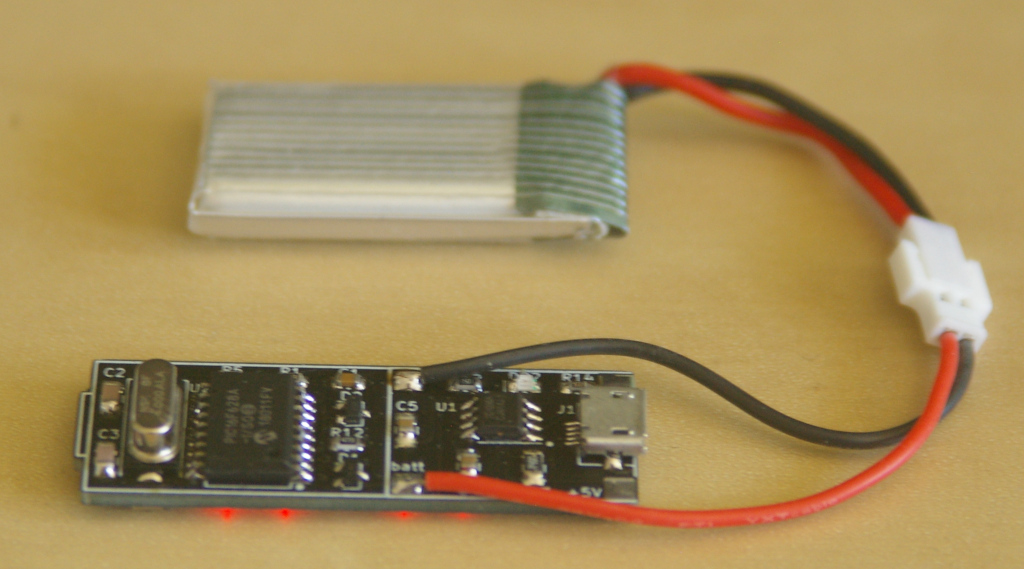

In this clock I did not use quartz crystal controlled oscillator. The Z80 has a non maskable interrupt, which I can activate at the corresponding pin. So I connected the power mains 50 Hertz to this pin. This frequency is precise enough in Hungary.

Lastly, I had to burn the self-depeloped program into an EPROM (27C64). I had only two empty EPROMs, and I did not have an eraser for them (just an old burner). But the Z80 developer and simulator program is great, I could make a working code with it. The first version had a little bug (did not reset itself at midnight). But the second EPROM worked perfectly.